Built for precise positioning and gluing flat products, such as CDs or samples, onto carriers such as journals or leaflets.

A larger Feeding and Affixing Unit can accurately place two or more products onto a single carrier.

This system dispenses and marks packaging flat products such as carton blanks.

Different marking units - labelers, inkjets, thermal transfer printers, etc. - can be integrated into the system. A compact solution for the marking of cartons.

Kora Packmat BF3-300 BasicFeeder series separates the blister cards out of a vertical magazine and dispenses the blister cards onto a conveyor. A flighted belt conveyor aligns the cards.

The laser printer creates a blue QR code by removing the blue coating of the blister cards.

The printed blister cards are transferred onto an outfeed conveyor for manual removal.

The system is designed for continuous mode with two or three shifts and adjustable for different format sizes. The touch HMI enables easy use and fast changeover times.

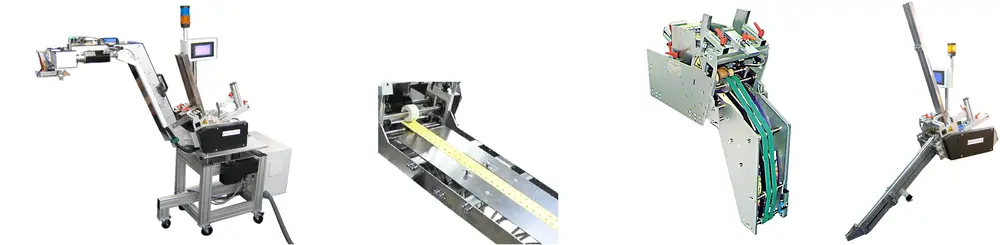

With the PouchCutter PC100 we have a competitve and cost-effective solution at a medium speed compared with the highspeed PouchCutter PC300 for the cutting of linked bags of e.g. desiccants, product samples or similiar products.

It is a compact cutting system with a machine speed of approx. 100 cycles per minute (depending on the product) for cutting and positioning linked bags fed from a carton box.

As the expert in feeding and collating systems, Köra-Packmat constantly develops new feeder options that meet customers’ requirements.

Here are some examples of special magazines we realized for different projects:

- Autoloader conveyor: Shingled placing of products (inline or 90°) on an autoloader to increase feeders’ autonomy. The autoloader is available in different lengths.

- Multiple magazines: For small products (phone cards) to increase feeders’ autonomy. The magazine is equipped with five shafts that are emptied automatically one after the next and convey the products to the feeder.

- Fan magazine: Perfect for the stacking and separating products folded or boosted on one side like brochures, cartons, folded leaflets.

For the vertical feeding of products, in particular, products that have to be fed upright. Suction feeder design.

Product guidance by suction. Readily accessible for integrating identification or monitoring systems.